Our focus in mold making lies in complex tooling projects for specific product groups, primarily within the automotive industry. One of our core competencies is the production of premium injection molds for speaker grilles, fabric-backed plastic components, and high-visibility parts made from PMMA.

We offer comprehensive, end-to-end solutions—accompanying our customers throughout the entire process, from the initial idea to the finished product. This includes application-specific consulting, design, assembly, and sampling. We also carry out maintenance and modification work quickly and reliably—even on molds from external sources.

Our range of premium injection molds is significantly enhanced by the advanced machinery of our sister company, Schweiger Tooling GmbH. For more information on their machining capacities, please refer to the Facts section of our sister company.

We firmly believe that “low purchase cost doesn’t equal low production cost”, which is why we place the highest priority on short cycle times and tool durability in all our mold designs.

We specialize in complex back-injected components for automotive interiors. Specifically, these include A/B/C pillar trims, roof endings, and foil back-injected seat back covers.

Components of this kind, produced with our molds and tools, can be found in nearly every German premium vehicle currently in series production.

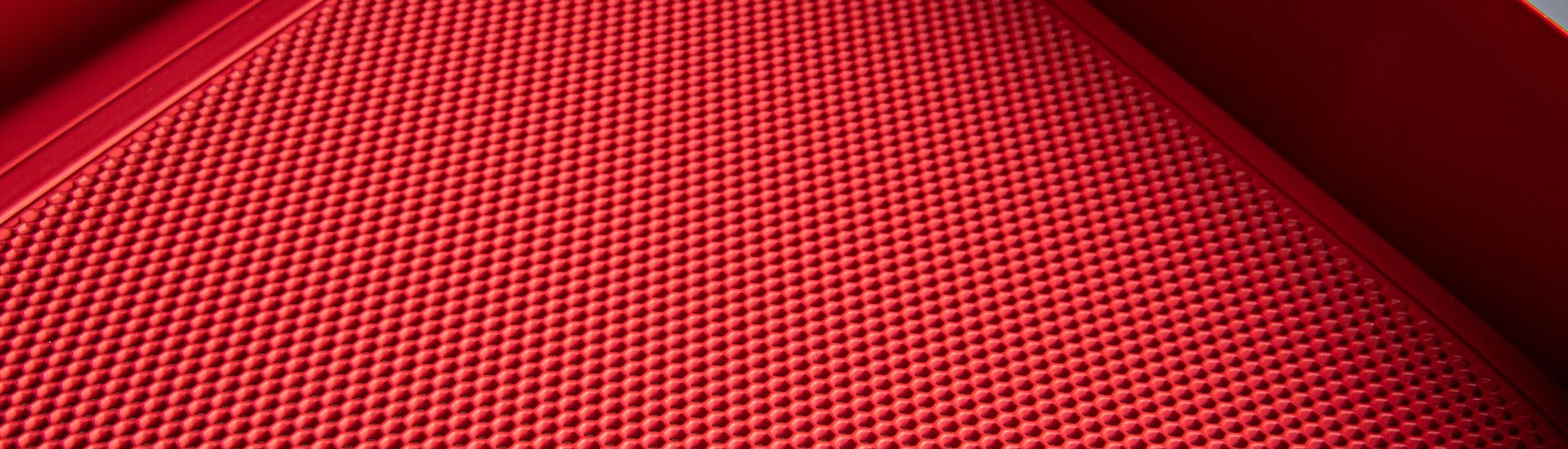

Plastic speaker grille structures and their various designs are one of our core competencies. No matter which German premium OEM or grille design is involved—you will find components of this kind in nearly every vehicle line, produced with molds and tools from Innsbruck.

Whether it's speaker grilles integrated into the instrument panel, doors, or pillars – we deliver precision and consistency across all applications.

PMMA pillar covers have become standard components in the exterior of modern vehicles and place high demands on surface quality. To address squeaking noises and other challenges in automotive engineering, these parts are increasingly manufactured using 2K and 3K technologies, making the associated molds significantly more complex.

These types of molds have also been among our core competencies for many years.

Visible parts place significantly higher demands on surface quality and, consequently, on the precision of injection molds. It makes no difference whether the components are used in interior or exterior applications. For decades, our core competencies have centered around molds and tools for visible areas. Today, our standard tooling portfolio also includes other visible parts such as trim strips, wheel arch liners (grained / painted), and more.

- Speaker grates of all designs

- Defroster / Ventilation

- Decorative panel (e.g. Variotherm)

- Decorative back injection molded parts (e.g. pillar linings)

- Film back injection molded parts (e.g. seat backrest covers)

- Door trim panels

- Steering column cladding

- Door - inner panels

- Light guide - Ambient light

- PMMA column linings (up to 3K)

- Chrome parts (Spoilers, Sill plates, Front grills)

- Wheelhouse trims (painted / grained)

- Door panels (painted / grained)

- Engine covers

- Planetary carriers

- Valve plates / housings

- Throttle housings

- Overmoulding molds

- Sinter molds

- Vulcanizing tools

- Conversion technology

- Decorative back injection incl. trimming in the tool

- Injection compressing molding

- Multi-components

- Stack molds

- Index plates

- Rotary plate

- Indexable inserts

- Internal gas pressure

- Variotherm (water / steam)

Ing. Johannes Driendl

Consulting & Sales

Manager

Christian Pröller

Consulting & Sales

Senior Manager

Oktay Güler

Consulting & Sales

Assistant