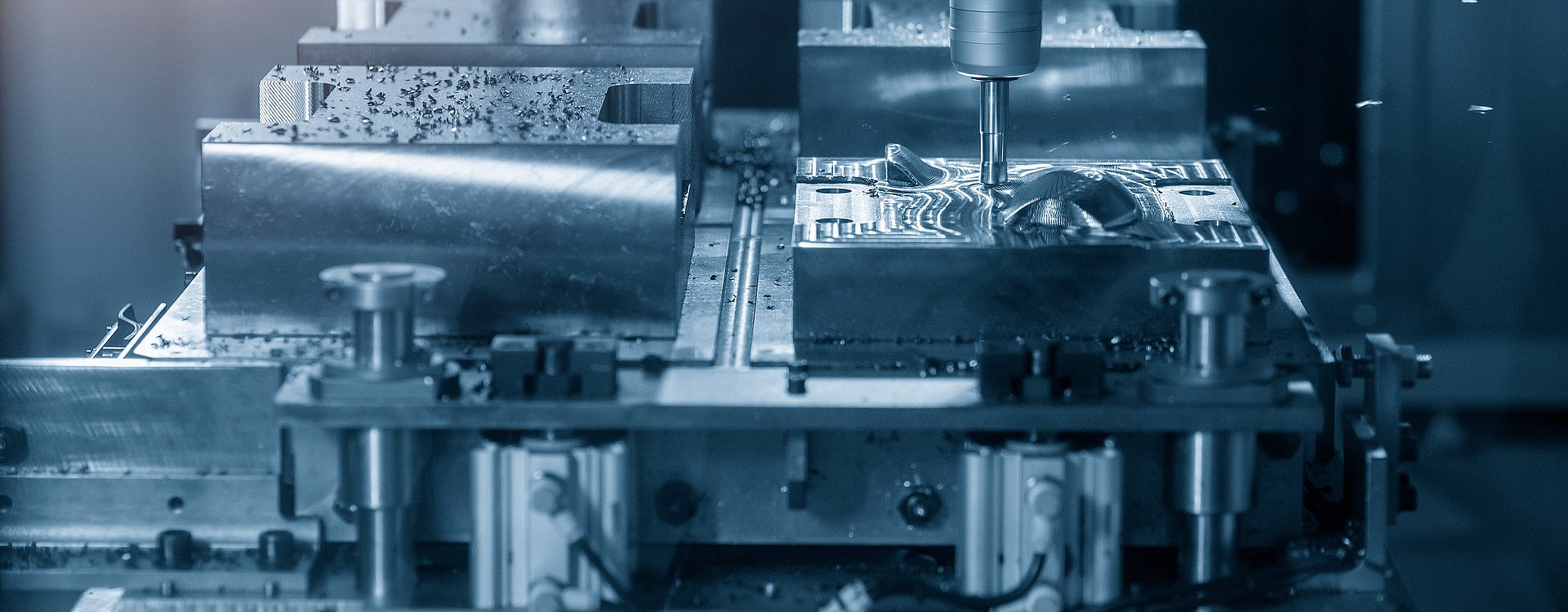

In the field of plant engineering and CNC contract manufacturing, we supply customers from the automotive to the semiconductor industry with complete systems, assemblies, and small series, as well as precision and custom parts made from a wide range of materials and geometries.

We offer all technologies in-house - from CAD design and CNC milling, turning, or grinding, to polishing and final assembly. Our size range is significantly expanded through the machinery of our sister company, Schweiger tooling GmbH.

Details regarding machining dimensions can be found in the Facts section on our sister company's website.

For more information on our machining technologies, materials, and the industries we serve, please refer to the sections below.

In addition to mold design for complex injection molding tools, our design department also supports plant engineering and CNC contract manufacturing as needed. Within the scope of our business partnerships, we provide tailored support for the development and drafting of systems, cold pressing molds, or other assemblies and components.

Turning is one of our core competencies and is performed in multiple shifts using state-of-the-art DMG machining centers. We are also happy to machine hard metal using turning processes.

Our machinery covers a wide range of dimensions - up to 380 mm in diameter on CNC machines and up to 450 mm manually.

We offer deep hole drilling services for workpieces with dimensions up to 1,200 x 750 x 990 mm, ensuring precision and efficiency even in demanding applications.

In the field of advanced CNC milling, our automated milling centers operate in multiple shifts to handle complex 3D and 5-axis machining tasks. We are capable of processing parts up to a size of 1,800 x 1,200 x 1,070 mm.

Upon request, we also machine hard metal as part of our milling services. For more information about the materials we typically work with, please refer to the corresponding section.

Our dedicated grinding department is equipped to handle the following size ranges with precision:

Cylindrical Grinding:

Up to Ø 500 x 1,000 mm

Surface Grinding:

Up to 1,000 x 600 x 425 mm

Profile Grinding:

Up to 500 x 300 x 150 mm

We also machine hard metal in all grinding processes.

EDM (Electrical Discharge Machining) is one of our core competencies. Our EDM department is equipped with 5 wire cutting machines as well as a hole drilling EDM machine, covering the following size ranges:

Wire EDM / Wire Cutting:

Up to 1,250 x 1,020 x 305 mm workpiece size

Hole Drilling EDM:

Up to 950 x 600 x 500 mm workpiece size

Sinker EDM, alongside wire EDM, is one of our core competencies and an essential prerequisite for premium mold making in plastic injection molding.

Of course, we also have the in-house expertise to manufacture complex electrodes with precision.

We cover the following size ranges:

Sinker EDM:

1,800 x 1,200 x 600 mm

Electrode Manufacturing:

700 x 700 x 400 mm

Experience-driven polishing is also an integral part of our daily operations. We perform finishing work both on special components and on electrodes for complex geometries that push the limits of manufacturability.

In our assembly department, highly skilled toolmakers work on complex premium injection molds from our mold making division, as well as on the assembly of assemblies and modules for our customers in plant engineering and precision parts manufacturing. The assembly team often works closely with the polishing department to achieve the desired surface treatment on the components.

Many of our customers appreciate having their parts and modules professionally and oil-resistant marked or engraved, allowing easy identification of part numbers and other information without needing a parts list or CAD drawing.

With our marking laser, we can engrave markings, symbols, and various types of inscriptions on different materials.

The marking area measures 330 x 330 x 42 mm.

Our measurement room forms an integral part of our ISO-certified quality management system. The measurement team has access to both tactile and optical measuring machines in a fully climate-controlled environment.

For our key clients in the high-precision parts manufacturing sector of the high-tech industry, we closely align by ideally using the same measuring machines and programs to eliminate any possibility of measurement discrepancies.

Additionally, we are capable of internally managing and providing essential aspects of a controlled quality management system. Examples include PPAP, FMEA, and CPK analyses.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Our customers in the abrasives industry manufacture products for a wide range of sectors. These span from automotive and commercial construction to shipbuilding, as well as honing and lapping technology.

Accordingly, our involvement in this sector is equally diverse. For example, we manufacture molds for powder forging, cold pressing tools, and saw cables used for cutting reinforced steel during the dismantling of oil platforms and ships.

With our plant engineering and CNC contract manufacturing division, we primarily and continuously supply our automotive customers with spare parts for their production lines.

Our range of components includes everything from positioning pins and gripper fingers to various spare parts for conveyor systems. Many of these customer relationships have spanned several decades.

Our customers in the semiconductor and high-tech industries operate both in the manufacturing of machines and EUV systems for chips and semiconductors, as well as in advanced medical technology.

We support the semiconductor sector by supplying highly precise components, such as so-called frames and other parts used for transporting coating materials on semiconductor wafers. We achieve the required cleanliness levels internally up to Grade 4, while Grade 2 cleanliness is provided in cooperation with an external supplier partner.

In the medical technology sector, we supply our customers with components and modules for the production of imaging devices, such as magnetic resonance imaging (MRI) machines, as well as highly precise semi-finished products, for example, carrier bodies used in the manufacturing of hip implants.

In the field of machine and plant engineering, we supply our customers with a broad range of precision components and assemblies made from various materials.

Our portfolio includes assemblies for the production of woodworking and grinding machines, as well as parts for filling systems. The punches and dies we manufacture for stamping and forming technology also serve as examples of our capabilities in machine and plant engineering.

Of course, we integrate the appropriate surface treatment processes - such as anodizing, coating, electro-polishing, chemical nickel plating, and blackening - into the manufacturing of components as required.

We supply the consumer goods industry with a wide variety of precision components used in the manufacturing of machines and systems for producing consumer products.

A good example includes complex shafts used in equipment for filling liquids into food packaging.

Our capabilities in the energy sector are diverse. Using our machine tools from various technological fields, we manufacture components for a wide range of power generation systems.

These parts must withstand extreme stresses, demanding high standards for material quality and precision machining - for example, in the production of complex geometries such as compressor blades and impellers.

Ing. René Bucher

Consulting & Sales

Senior Manager

Ing. Patrick Ringler

Consulting & Sales

Manager

Thomas Wildauer

Consulting & Sales

Senior Manager